WAFTEC Equipment Filters Which Support

Industries around the World behind the Scenes

SCROLL

SCROLL

Domestic

share※

90%

or higher

More than

10,000

units

delivered

Established in

1952

Emulsion

Emulsion Coalescing on

Coalescing on Remove from

Remove from

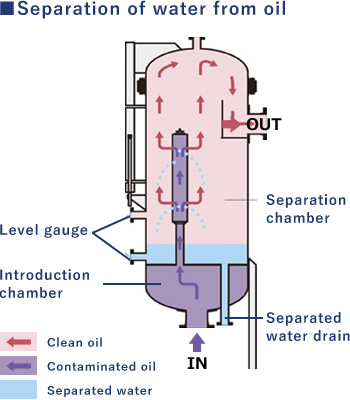

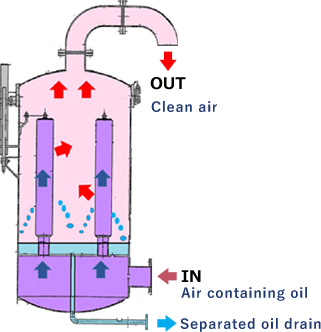

A Coalescer cartridge has a special multi-layered structure which instantaneously breaks down the emulsion (clouding) by running the fluid through the Coalescer cartridge in the direction IN -> OUT. Separation occurs due to the difference in specific gravity between fluids.

The flow of the fluid proceeds as shown above, and coalescing is conducted on the dispersed fluid particles of 0.5 to 50 μm within the Coalescer cartridge to let them grow to droplets of 2 to 6 mm. Separation is addressed by the specific gravity of each fluid, and only the necessary fluid is sent to the later stage of the process.

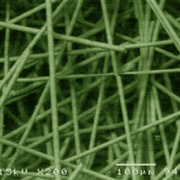

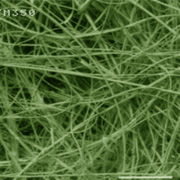

WAFTEC changes the media of the Coalescer cartridge to suit the characteristics of the fluids handled by the customer.

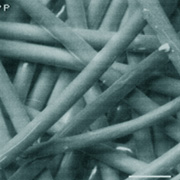

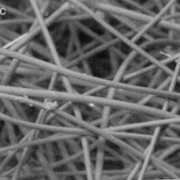

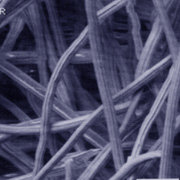

In general, glass fiber is popularly used by many plants, and carbon fiber is recommended if the fluid reaches high temperatures.

Glass Fiber (normal)

Glass Fiber (normal) Glass Fiber (fine)

Glass Fiber (fine) Polypropylene

Polypropylene Carbon fiber

Carbon fiber Rayon

Rayon| Viscosity | Main fluid under 50mPa・s Intermingling fluid under 300mPa・s |

|---|---|

| Density difference | Over 0.3g/㎤ |

| Interface tenstion | Over 3mN/m |

| PH range | 1~14 |

| Operating pressuer | Over 0.1Mpa |

| Operating temperature | 0~300℃※1 |

| Amount of Solid | Under 1mg/L |

WAFTEC R&D Center is the only filter manufacturer in Japan which owns testing facilities.

Capable of Process Coalescer testing on various fluids. We offer optimal proposals for our customers.

We also provide extensive after-sale follow-up services for problems that occur after the equipment is delivered.

We help customers solve their problems through analysis on products after use.

Filter Water Separator

Filter Water Separator Process Coalescer

Process Coalescer Oil Mist Separator

Oil Mist Separator Oil Purifier

Oil Purifier Portable Filter Water Separator

Portable Filter Water Separator

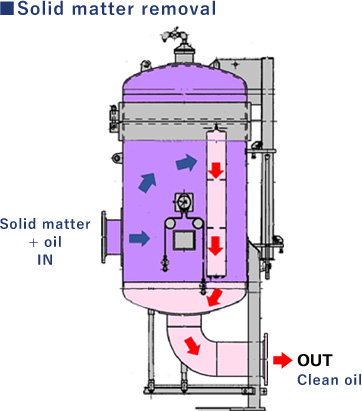

By passing fluid such as oil or water containing impurities through the cartridge in the direction OUT -> IN, the fluid and impurities are separated.

Only the necessary fluid is sent to the later stage of the process.

Micro filter

Micro filterPlease feel free to contact us for questions on our products, technical consultations, or requests for quotes.