Antiviral photocatalyst coatingW care coat

About photocatalysts

Photocatalysts are a technology that was born in Japan, and it broadly refers to materials that absorb light and create a catalytic action (promote a chemical reaction). Light is used to create a chemical reaction that is difficult under normal conditions. Photocatalysts are able to break down organic matter and bacteria by promoting oxidation-reduction reactions. With the spread of infections caused by current viruses and bacteria, photocatalysts are being used more and more as a method of preventing infections. A crucial step in preventing infections it is to maintain the hygiene of areas that have a high risk of infection.

Antiviral photocatalytic coating W care coat series

The characteristics of W care coat using a photocatalyst of Wako Filter Technology is that it can provide antiviral and antibacterial effects, even in dark places. Instead of the conventional method of photocatalytic effects that were difficult to achieve in indoor environments with fluorescent lamps or other sources, it uses the effects of a catalytic promoter that assists with the reaction.Moreover, the titanium oxide particles were made finer so as to increase the adhesion and activity.In continuing our development of products backed by evidence, we will continue cooperating with public research institutes and universities to perform research using infectious viruses and bacteria.

Characteristics of W care coat

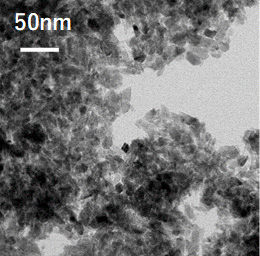

The titanium oxide particles used in W care coat are much finer than conventional ones, so they provide superior photocatalytic activity and adhesion.

Some of the technical data about W care coat is provided below.

Properties of W care coat particles

| W care coat | Conventional titanium oxide | |

|---|---|---|

| Particle size | Less than 10nm | Up to 50nm |

| Electron microscope image |

|

|

| Shape | Prismatic(pointy) | Spherical(round) |

Antiviral capabilities of W care coat

| Luminance | Fluorescent light for home use (visual light) 500 Lux* (UV cut conditions) *500 Lux: The same brightness as indoors |

|---|---|

| Type of virus provided | Novel coronavirus (Strain provided by National Institute of Infectious Diseases) |

| Viral load in test solution | 2.5×107PFU/mL |

| Evaluation sample | W care coat coating film |

| Test method | References: JIS R 1756 (Antiviral test of products treated with photocatalysts) and ISO 21702 (Measurement of antiviral activity on plastics and other non-porous surfaces) |

| Test period | Japan Textile Products Quality and Technoloigy Center |

-

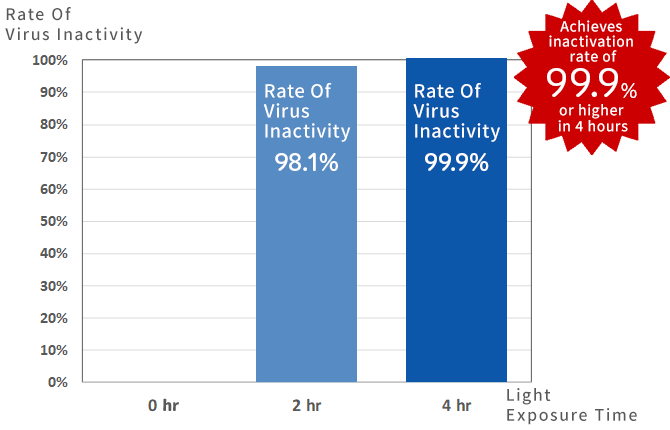

Changes in virus inactivation in surfaces coated with W care coat (graph)

- We confirmed that the viral activation on surfaces coated with W care coat changes over time.

- On the sample surface coated with W care coat, novel coronavirus broke down over time, and it was confirmed that there was a decrease of 99.9% in the viral infectivity after four hours.

- It was confirmed that the coating decreases the viral infectivity even under conditions where there is no photoirradiation (equivalent to the amount of light in a room at night).

- These results demonstrated the same degree of virus inactivation as the antiviral test results on the bovine coronavirus that had been conducted earlier. This suggests that the same antiviral effects can be expected with mutations of the novel coronavirus.

(Viruses 2020, 12, 1372; Application of a Photocatalyst as an Inactivator of Bovine Coronavirus)

- Virus inactivity:Decrease in the infectiousness of a virus

- Rate of virus inactivity:The rate of decrease in the infectiousness of a virus

- Virus infectivity:The ability of the virus to infect cells (many viruses have an infectivity that increases with the viral load)

- These test results do not guarantee prevention of viral infections.

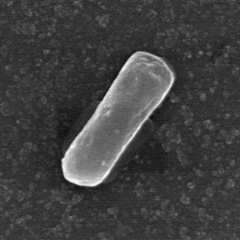

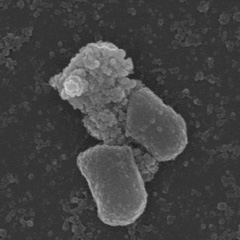

Antibacterial capability of W care coat

We observed changes to the morphology of bacteria (E. coli) on surfaces coated with W care coat.

Photocatalyst caused the outer membrane of the bacteria to break down, thereby making the shape of the bacteria unstable(photos on the rightphotos on the bottom)

Before photoirradiation

4 hours after photoirradiation

Hygiene measures using W care coat

In addition to vehicles such as buses and trucks, W care coat is used in a variety of everyday environments.

- ■ Fixed-route, sightseeing, and other buses

- ■ Large vehicles, such as trucks

- ■ Medical facilities, such as hospitals or nursing facilities

- ■ Childcare facilities

- ■ Evacuation centers

- ■ Restaurants

- ■ Offices

- ■ General housing

Enterprises that use W care coat (titles omitted, non-alphabetical order)

Client(Honorific titles are omitted、in no particular order)

- ・Keihin Kyuko Bus Co., Ltd.

- ・Nagasaki Electric Tramway Co., Ltd.

- ・Hakodate Bus Corporation

- ・Chikuma Bus Corporation.

- ・Car Conveni Club Co.,Ltd.

- ・Kurobe Lake Pleasure Boat Garube

- ・Kanden Tunnel Electric Bus

- (Excerpt)